Welcome to Piezography Pro

Piezography Pro inks introduced in 2017 designed for 9 and 11 ink position printers makes the highest-quality fine-art monochrome prints in the world. With the industry’s best dMax, highest resolving fidelity, visually balanced toning options, and most uniform gloss, Piezography Pro has it all.

Piezography Pro’s new pigment and curve shaping technology, enable one million toning variations and industry-leading dMax on more than 30 different fine-art papers out of the box.

Gloss “chroma” optimizer is printed at the same time as the ink. Piezography Pro gloss far surpasses the newest Epson SureColor and Canon Pro printer systems even with printers a decade old.

At our research and proving grounds, Cone Editions Press, we’ve experimented with black ink from all over the world. Piezography Pro is the darkest dMax (blackness of black) we’ve ever measured in-lab.

The Piezography Pro ink system comes with a set of tools and documentation for calibrating and tuning your workflow to enable consistency and tonal fidelity unparralled by any other system.

ARTIST-MADE

Piezography Pro is made at Vermont PhotoInkjet in Vermont: an artist-led, innovative, inkjet technology company with deep roots in the formation of fine-art inkjet as we know it today.

LONG TERM SUPPORT (LTS)

For labs, it’s important that the ink stay consistent from batch to batch. With updated in-house quality-control systems and software, Piezography Pro meets that need head-on.

NEW DOCUMENTATION

Pro comes with The Piezography Manual Deluxe Edition covering everything from advanced K7/K6 & Pro curve modifications, linearization, studio maintenance, and more.

CONTINUAL UPGRADES

As new printers and papers and spectrophotometers come out over the coming decade, Piezography Pro curves and tools will change to meet the requirements!

BLENDING

Piezography Pro utilizes two inksets: warm and cool. These finely balanced ink hues make neutral when combined together at certain percentages enabling very creative control of the warm, neutral, and cool axis. Up to one million unique toning combinations can be achieved all from a single printer.

Neutral

Warm

Cool-Neutral

Neutral Shadows, Warm Highlights

Warm Neutral

Warm-Neutral Shadows, Cool-Neutral Highlights

Want to stay informed?

GLOSS OPTIMIZED

Piezography Pro has a newly invented micro co-polymer Gloss “chroma” Optimizer that surounds each carbon/pigment particle in the ink and is also extended within a final “clear” ink channel. Piezography Pro encapsulates the entire gloss print under a protective layer from edge to edge all at the same time as the inking: no need to do a second print pass with the optimizer.

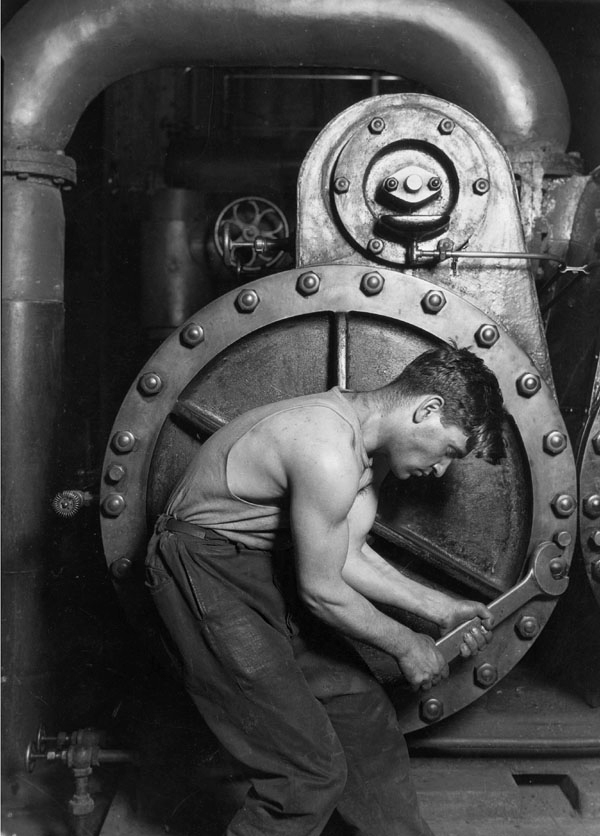

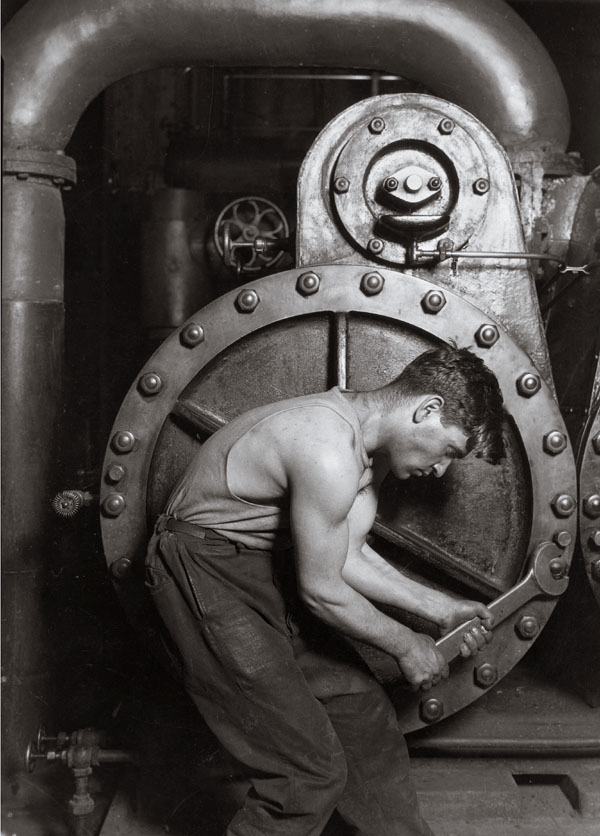

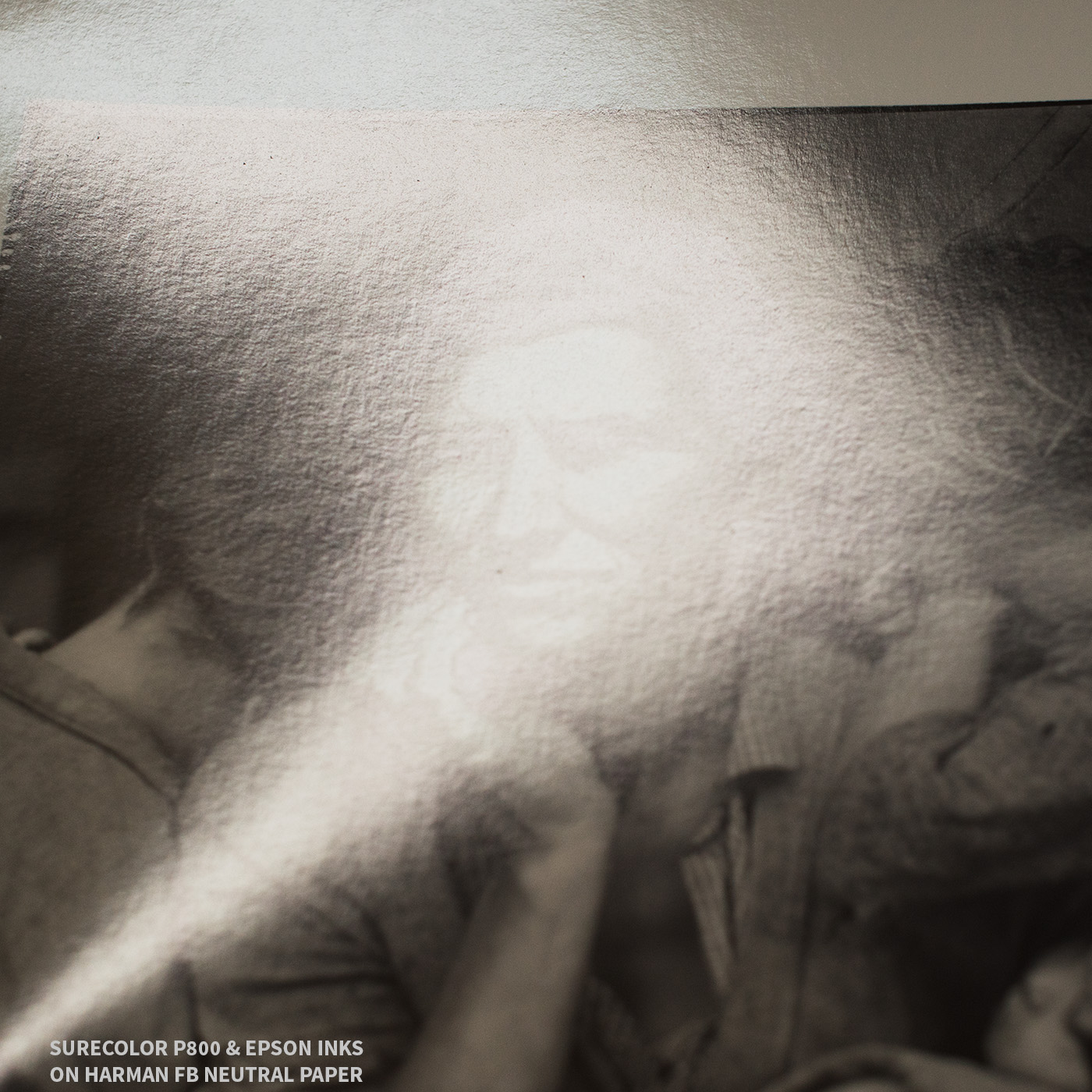

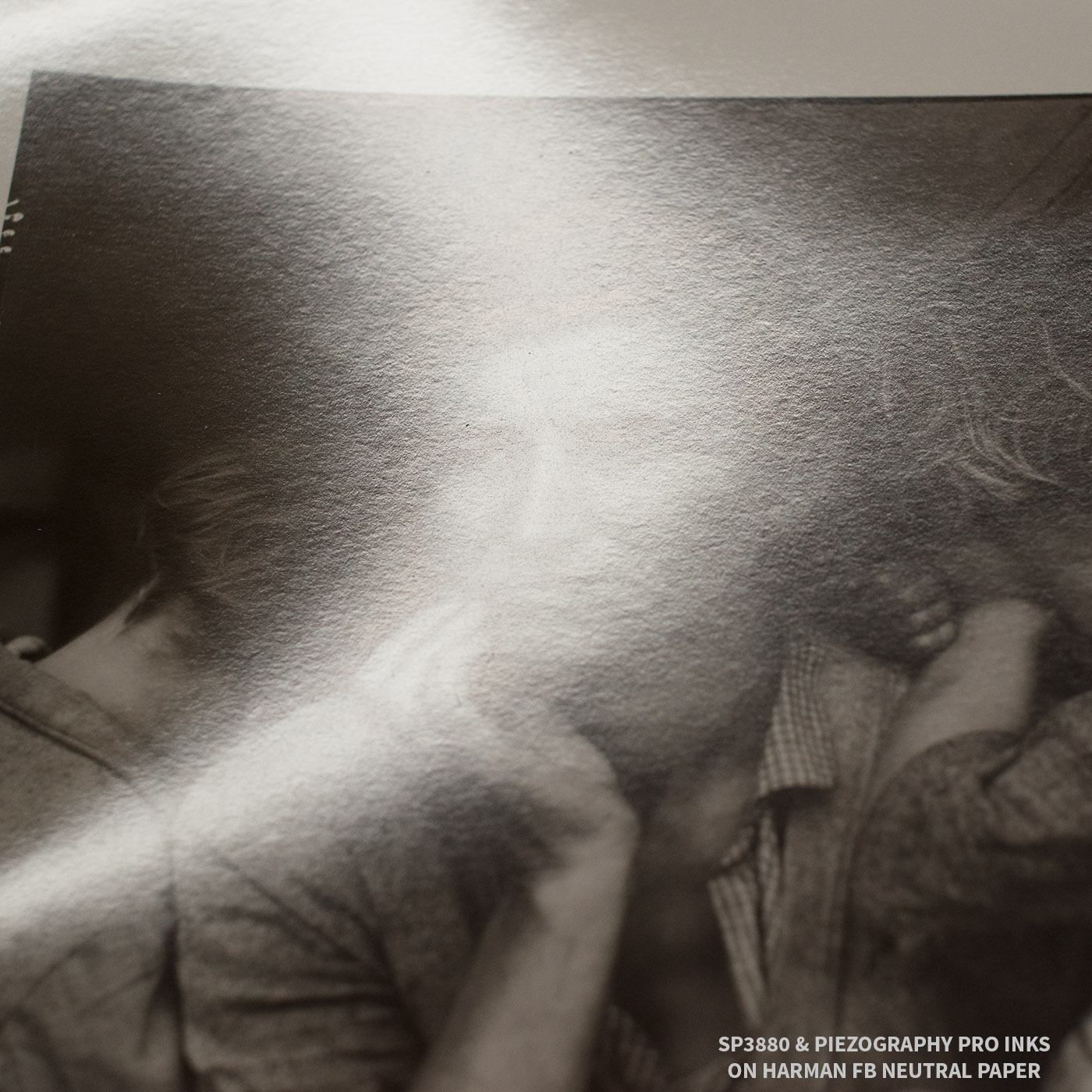

We printed a portrait on one of the hardest gloss papers to print correctly: Harman Gloss FB Neutral. We printed with a brand-new Epson SureColor P800 (above on the left) with Epson UltrachromeHD inks installed. Then we did a print on a much older Stylus Pro 3880 with our new Piezography Pro inks installed (above on the right). The visual results speak for themselves.

Not only is there no gloss differential between the white of the paper and the inked image, there is 90% less visual bronzing than Epson’s most recent inkset. Because the white of the OBA paper is also encapsulated by gloss optimizer, it no longer fluoresces and its color remains uniform under all different light sources.

SUPER DARK DMAX* (Blackness of Black)

When dMax is measured, it is generally communicated in terms of “Density”. When measuring matte blacks this is fairly straightforward. On Hahnemule Photo Rag paper, the new Piezography Pro Ultra HD matte black ink produces a density of 1.84 which is significantly darker than the Epson 9900 matte black (1.65) or the latest Epson P-800 matte black (1.75). Ultra HD is the darkest matte black ink on Earth!

When measuring photo blacks, density values are (often) arbitrarily calculated from the more scientifically standard “Luminance” values given by all of the various machines that measure reflected light. Luminance is the percentage of light reflected from a print. The conversion from Luminance to Density when it nears 3.0 is not exactly standard from one company to another, so each time a printer/ink company claims a certain density milestone (say Epson’s claim of 2.84 on Ultra Premium Glossy paper), it’s important to do the actual testing based on the more truthful Luminance standard. This way apples are not compared to oranges. We happen to have a brand-new Epson SureColor P800 in our R&D lab and we decided to test our new Piezography Pro ink against Epson inks using an older 3880 printer filled with Piezography Pro inks.

PROFESSIONAL TOOLS

Give artists ink and they’ll make prints. Give artists tools to calibrate that ink, and they’ll produce prints for a lifetime. Piezography Pro Edition comes with hundreds of stock profiles but also makes calibration fully DIY and liberates every artist’s creative potential.

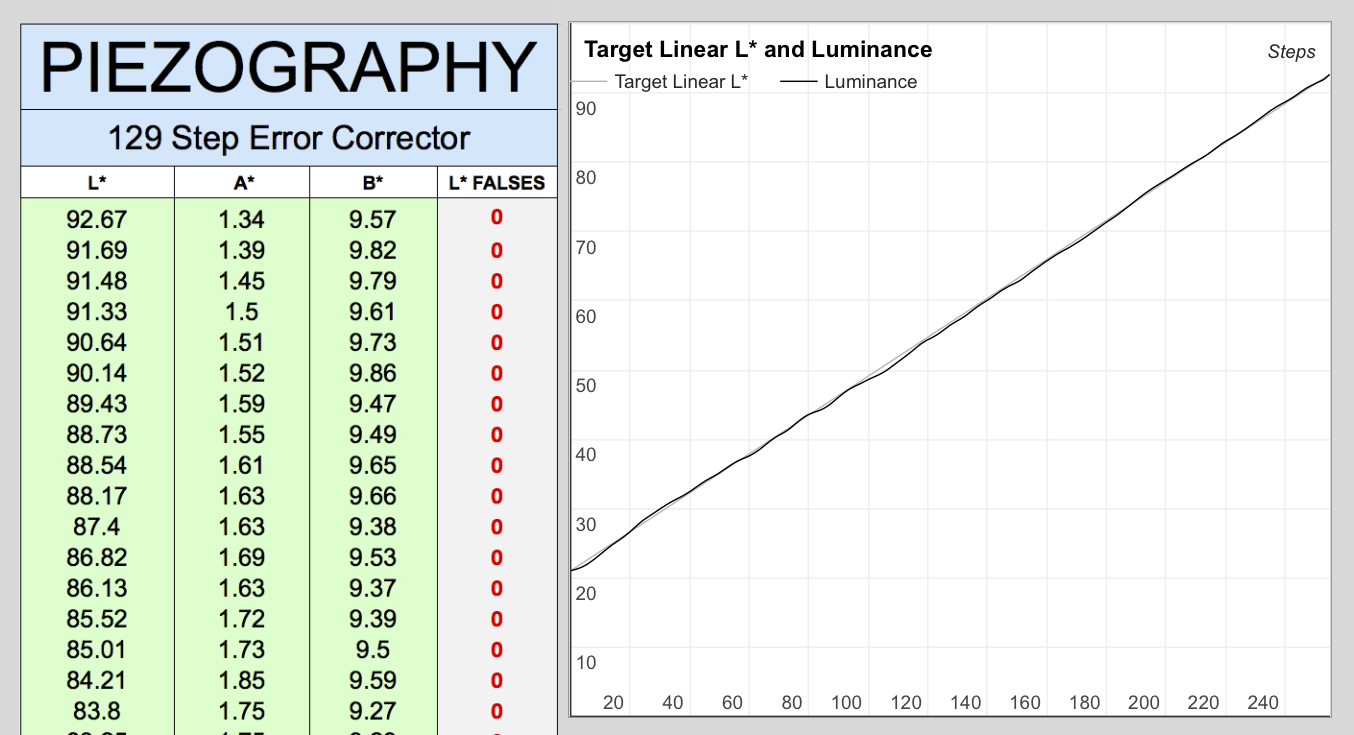

129 STEP ERROR CORRECTOR

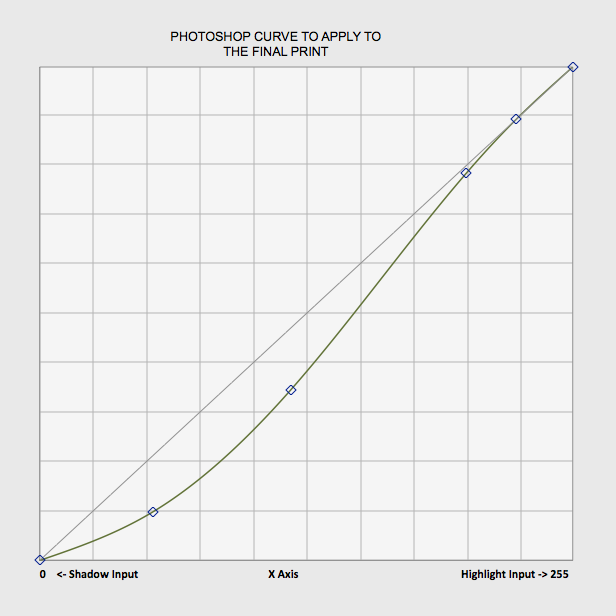

The 129 step Error Correction Tool is used to measure a final 129 step target and calibrate the final perfect Piezography curve. This tool is at the heart of the calibration process.

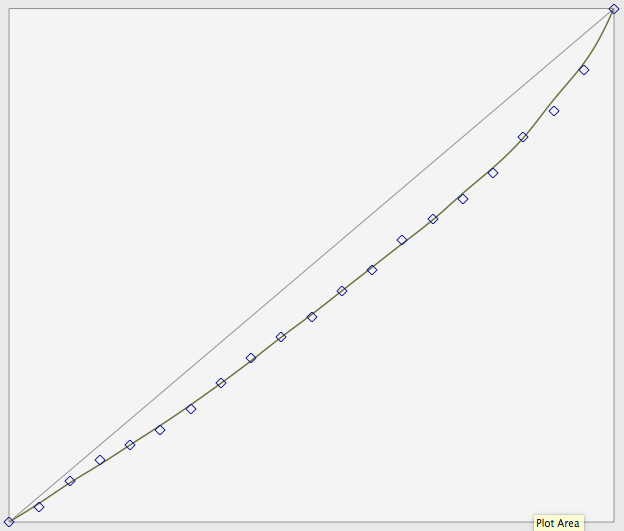

CURVE ADJUSTMENT TOOL

This revolutionary tool allows you to make a Photoshop adjustment curve and then directly burn that adjustment curve into a Piezography “.quad” curve as a “tuning intent.”

DELUXE PIEZOGRAPHY MANUAL

This manual is ever growing. It includes extra chapters on how to Linearize Piezography and how to calibrate the PiezoDN negative.

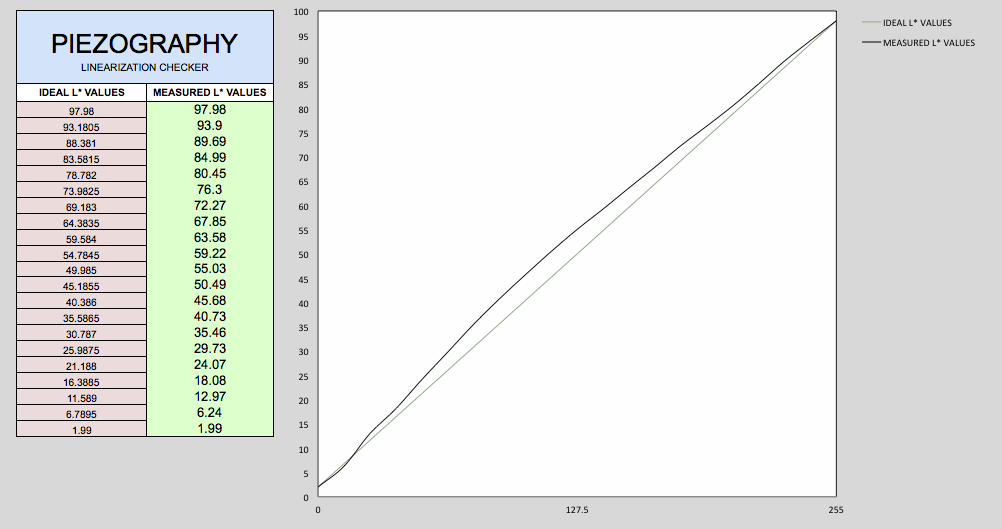

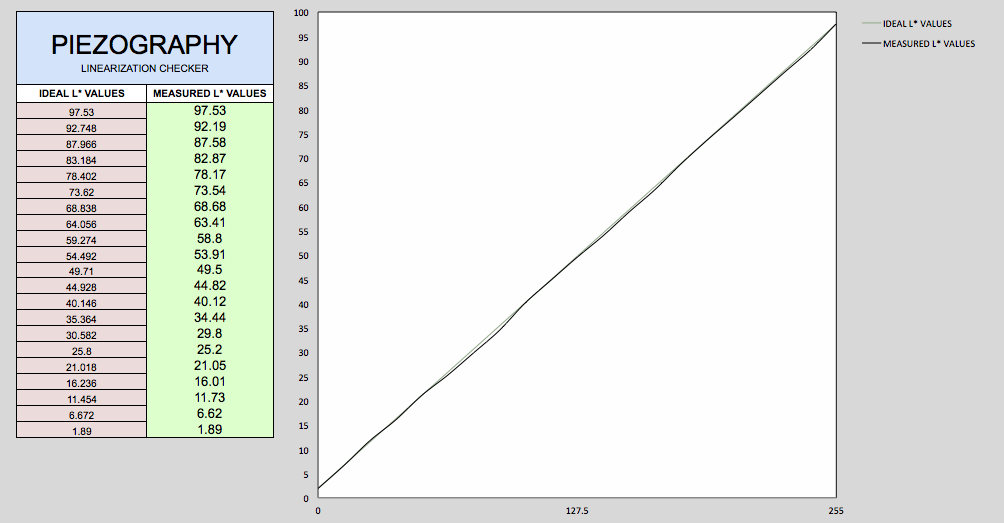

21 STEP SCANNER TOOL

This tool allows you to print a 21step target, scan it in with a good scanner, and linearize a Piezography curve with the scanned values.

Piezography Pro F.A.Q.

What is the primary difference between Piezography K7 and Piezography Pro inks?

Piezography K7/K6 inks were designed for EPSON 6 and 7 ink channel printers as a purely monochromatic ink set capable of producing only one tone and required the shifting of the paper color to change that tone. They were produced in pure carbon, warm-neutral, selenium, cool neutral, and special-edition. Further, while matte printing was acheived in one printing K7 required a second printing for glossy and baryta papers to apply the gloss overprint. They have fallen out of use to the degree that these inks are no longer being formulated and whatever remaining inventory is all that remains.

Piezography Pro inks were designed for EPSON 9 and 11 ink printers. It is a more modern approach to fine black and white printing including 3 or 4 shades of a warming ink and 3 or 4 shades of a cooling ink. The inks are both matte/glossy compatible so that the Gloss Overprint can be printed simultaneously with the inks. An extremely dark black matte black ink was introduced with this inkset as was a darker than usual photo black ink.

The inks are designed for use with three provided curves per media. The warm, neutral, and cool curves can be blended or split-toned to produce literally more than a billion possible variations.

Can Piezography Pro inks be used in EPSON 6 and 7 channel printers.

We do not provide any support for their use in printers that do not have at least 8 ink channels.

Can K7 and Pro inks be intermixed?

While they are chemically compatible we do not provide any support for this.

Can I use my existing K7 cartridges with the new Pro ink?

We suggest that you keep things clean and organized and get new carts. However, if you are on a budget, you can clean the cartridge out very carefully with distilled water (!!!), let it drop out over night, and fill with Pro ink.

Do I need to PiezoFlush my printer to install this ink?

If you are going from a Piezography K7 to Pro ink set, no. We suggest you PiezoFlush your printer between color and Pro, however, this is entirely up to you. Color staining is not as much of an issue when going from Color to Pro as it was from color to K7, but it’s still there. It takes a lot of ink to completely eliminate color in printer dampers and PiezoFlush can save you money and then you have a flush kit at the ready.

Does PiezoDN Digital Negative curves work with Pro?

Yes. We have built PiezoDN master curves for the Pro inks. In fact, the Piezography Pro inks produce better digital negatives than do the K7 inks and we have spent more time developing alternative process curves and workflow for Piezography Pro inks now that K7 ink is in the discontinuation process.

Do I need to let my print dry and then print a GO pass over it like K7 printing?

No. The new Gloss Chroma Optimizer prints at the same time as the ink.

What is the UltraHD Matte Black dMax?

We are measuring a dMax of 1.81 on Hahnemuhle Photo Rag paper with this new ink and as high as 1.87 on Hahnemuhle Bamboo. We used to measure about 1.64 on Hahnemuhle Photo Rag with our original matte black ink. Ultra HD is nearly a photographic stop darker than the OEM.