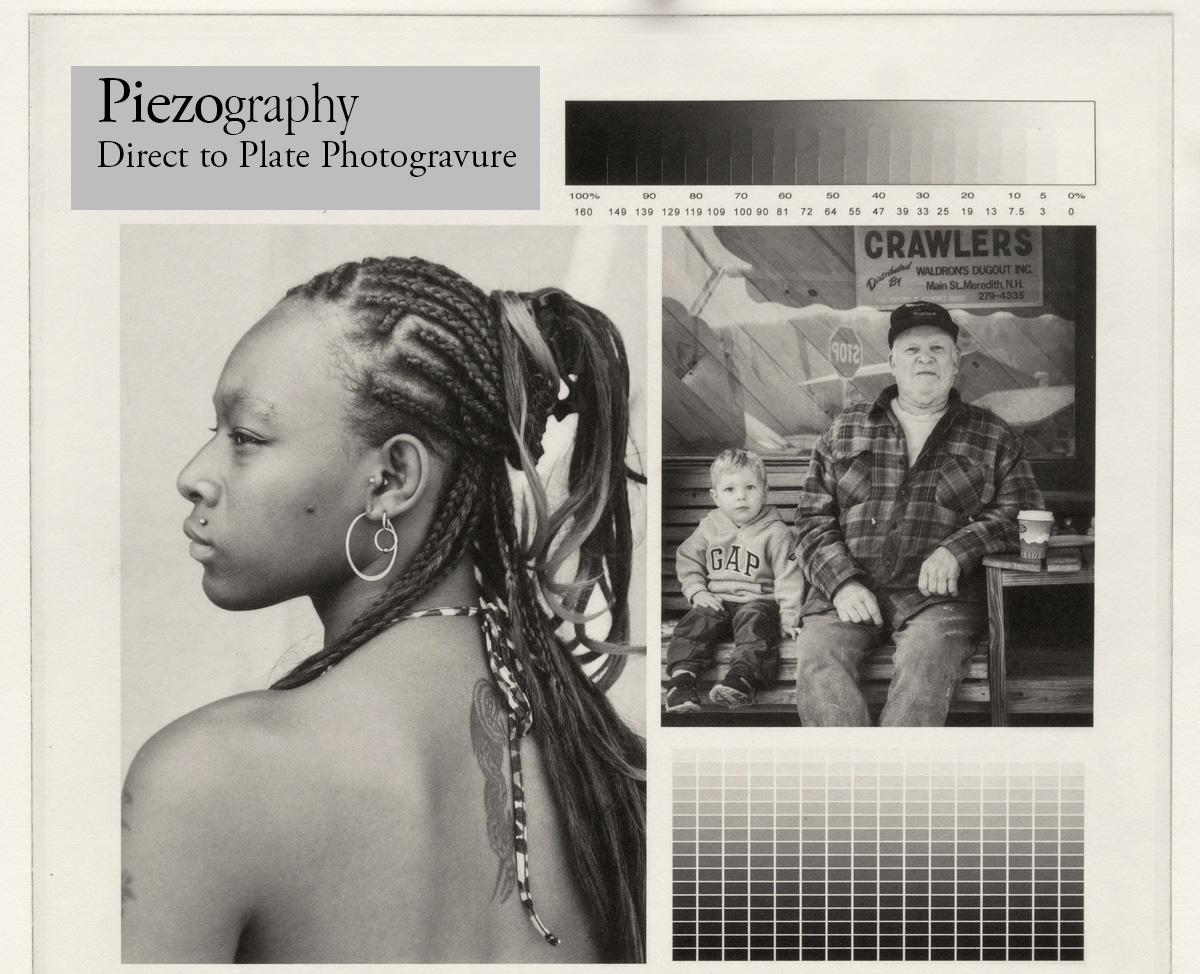

About Piezography 4-inkjet Direct to Plate Photogravure

Instead of the traditional film positives and exposing screens made of dot patterns, we invented a system using 4 shades of Piezography UV absorbing inkjet-ink & Piezography software that print the positive image directly to the surface of a special photopolymer plate at a resolution of 2880 dots per inch that can then be exposed directly to UV light. These 4 multi-overlapping, inkjet-inks produce tens of thousands of more gray levels than can film and dot.

These gray levels are successively less & less opaque to UltraViolet light and the slow to expose Piezography Photogravure Plate becomes successively more & more resistant to being hardened. That’s a beautiful marriage of inks and substrate that once processed with simple water produces a plate with an unusually long and smooth tonal range for photogravure and results in prints that rival the smoothness of platinum printing. It is dotless; a new construct for photogravure. And it includes two methods which produce prints that match images on calibrated or non-calibrated displays.

Most of the inkjet-ink droplets are microscopic in size and too closely packed to be visible by the human eye. Because of the absence of film and glass, the exposure to Ultraviolet light causes these tiny grains of ink to form perfect undiffused divots of varying depth in the surface of the plate that when inked, wiped, and printed on an etching press cannot be seen in the print even with the strongest loupe. You can think of it as a microscopic aquatint.

We illustrate below how this is achieved:

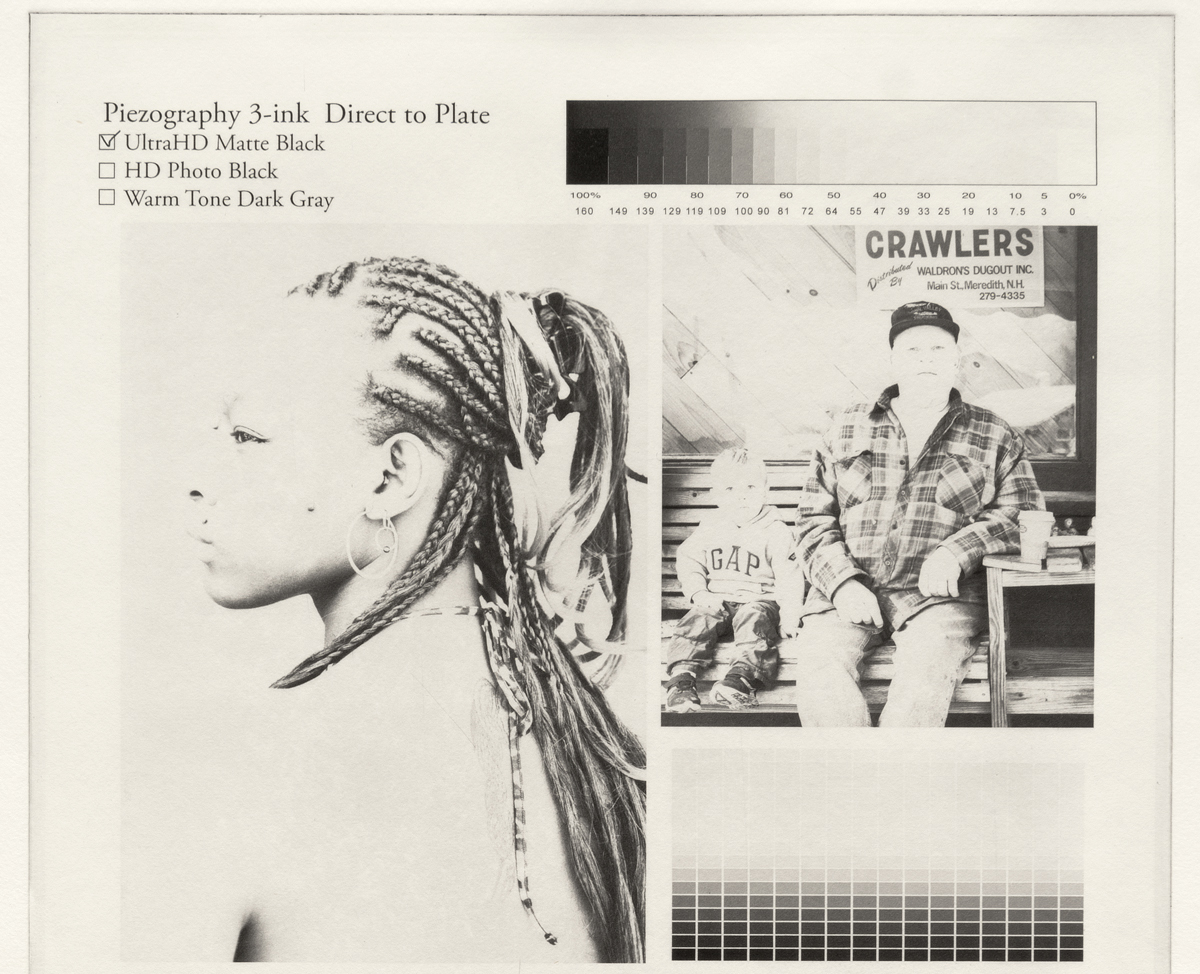

Piezography inkjet ink #1: UV opaque

To illustrate how we do this we isolated only the most opaque inkjet ink using an independent channel printing software and inkjet printed the Piezography Photogravure Plate with only the most opaque of the 4 inkjet inks. The other three inks were turned off. We exposed and processed the plate. Then we hand inked, wiped and printed the plate with an etching press using Copperplate Warm White paper to show as an example what only the most opaque inkjet ink is responsible for when using the 4-ink Direct to Plate process. The opaque inkjet ink (inkjet ink #1) produces only the shadow range but does so without introducing dots that are perceptible to human vision.

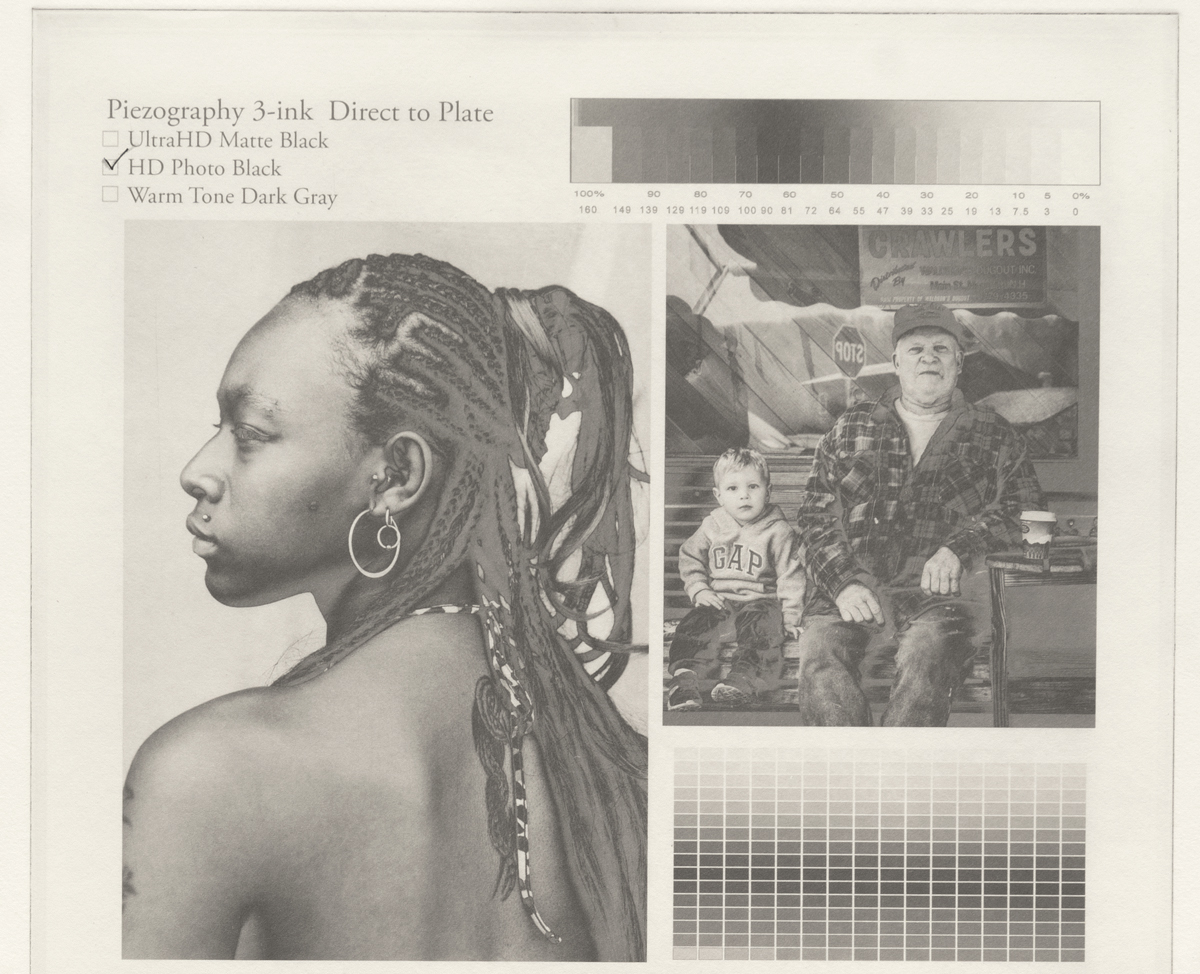

Piezography inkjet ink #2: UV near opaque

Then we isolated only the nearly opaque inkjet ink (the other three inks were turned off) and inkjet printed another Piezography Photogravure Plate, exposed and processed it. Then we hand inked, wiped and printed the plate to show you only what the nearly opaque inkjet ink is responsible for. The nearly opaque inkjet ink (inkjet ink #2) produces the mid-tones without compromise. You can see that it underlaps the shadows which will further smooth out and eliminating the visibility of those dots. The same carbon etching black ink used to print the first plate is used again to print this plate. The reason it is not as black as the first print is because the dots produced by inkjet ink #2 were not as opaque as inkjet ink #1 and therefore produced much shallower dots in the plate that much less etching ink can be pushed into. And when all four inks are printed at the same time, this same effect occurs.

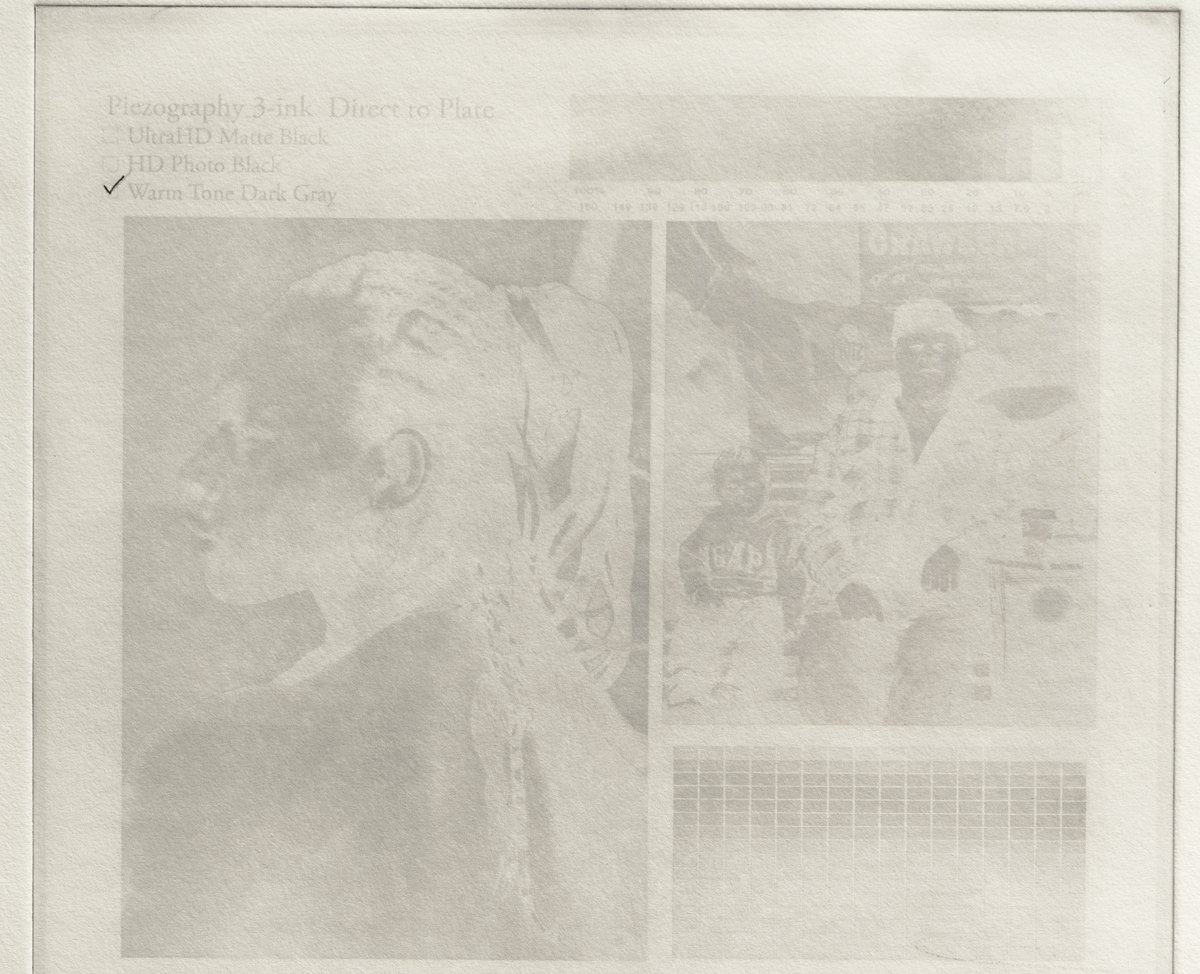

Piezography inkjet ink #3: UV semi-transparent

Finally, we isolated only the semi-transparent inkjet ink (the other three inks were turned off) and inkjet printed another Piezography Photogravure Plate, exposed and processed it. Then we hand inked, wiped and printed the plate to show you that the semi-transparent inkjet ink is only responsible for producing the highlights and without compromise. You can see that it underlaps the mid-tones which will further smooth out and eliminate the visibility of those dots. Your eyes would not be able to discern these highlight dots because we have printed them so tightly close together and the value of gray is too light to see. Were they not printed this way we would need lots of dark dots spaced far apart to assimilate such a light tone. Inkjet ink #3 is so transparent, and yet Piezography Photogravure Plates are so sensitive, that during the exposure – and the same exposure time is used for all three of these tests… the divots formed are so shallow that the same strength of carbon black etching ink used in the previous tests prints prints as light as you see in the print.

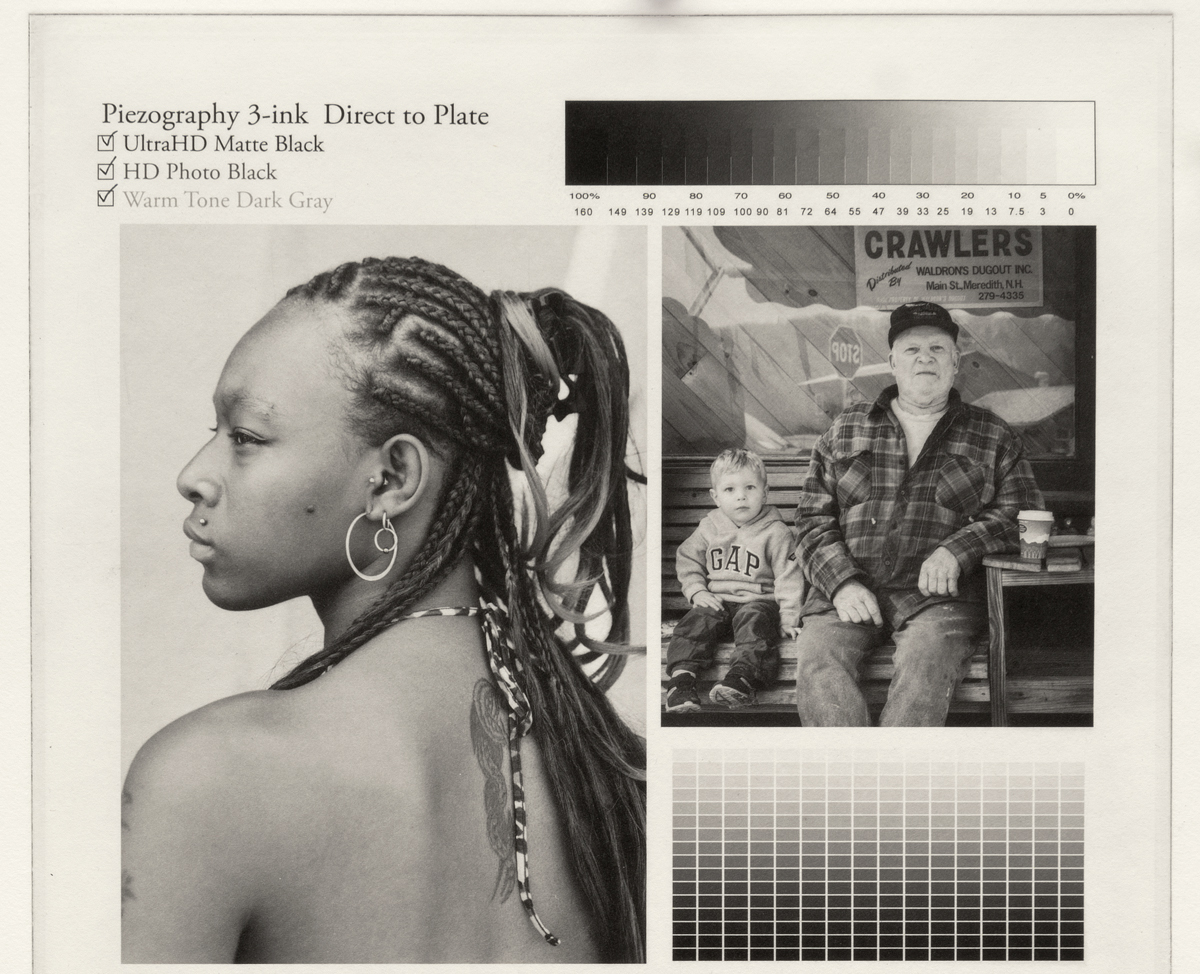

Piezography inkjet inks #1, #2, #3 and #4

In this example, we printed a fourth plate but this time using all 4 of the inkjet inks together in the normal way that we use and teach and how you will if you purchase this product. What is impossible to illustrate with photos is the fourth ink which is used for white and near white in the final print allowing us to control the exact amount of desirable “plate tone”. For you it makes the plate margins exceptionally easy to wipe, but it can be adjusted to create a just as easy to wipe overall plate tone something that normally is only achievable with years and years of press experience.

This is a pre-calibrated process which explains why the tonal scales are so perfect. The end results are dotless, smooth, high in acuity, and easily separate 256 gray values. And this product is now available as a turn-key product for a number of supported printers in which only four ink channels need be working. You may be able to find one of these printers for free. Piezography inks have a reputation of being much easier on print heads than OEM color pigment inks. Best of all, you do not need to purchase expensive calibration equipment and software. The system is designed to produce these results when you use the Piezography inks on a supported printer with our software and Piezography Photogravure Plates.